Features

Enhanced Security in Change Management

Automatic checks detect conflicts, risks and dependencies before they become a production problem.

Invalid transports are a common cause of instability in SAP landscapes. SmartChange automatically analyzes every transport for risks, dependencies, and completeness, preventing downtime, re-imports, and manual rework.

SmartChange Quality Checks in detail

SmartChange systematically checks every transport request and identifies typical risks at an early stage.

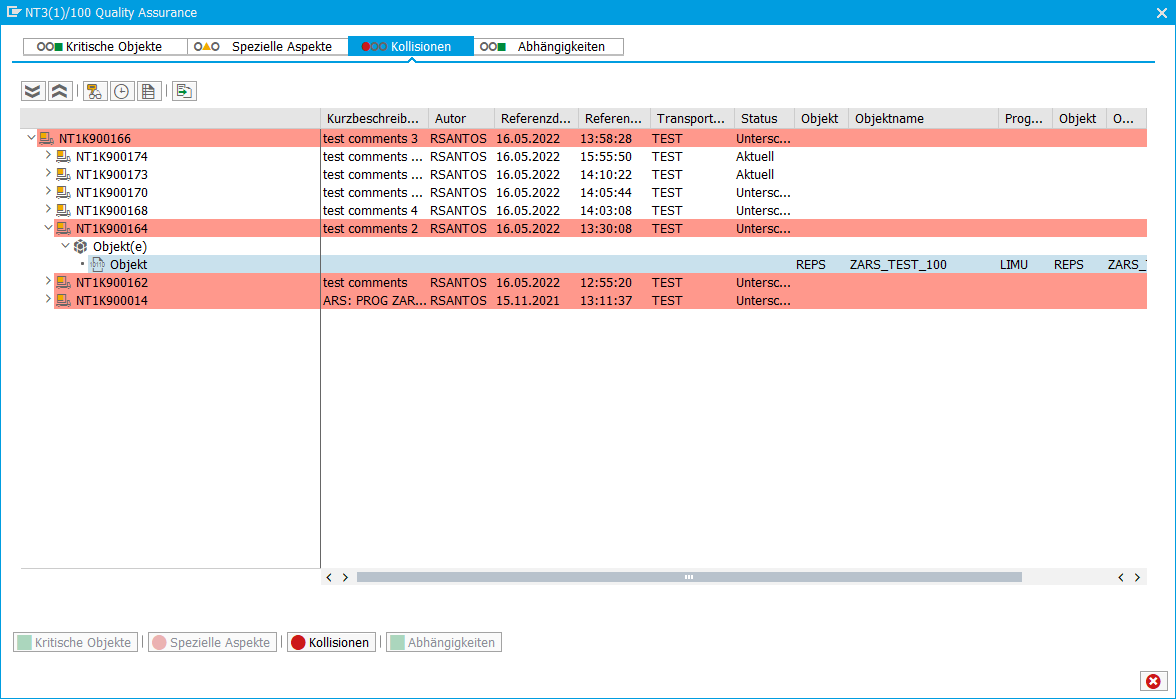

Collisions and Overtakers

Through extensive automated checks, REALTECH SmartChange makes it possible to avoid typical risks for productive SAP systems. The collision check indicates when identical or overlapping objects are in separate SAP transport and if there is a risk of version overtakers.

Overwrite

If version overtakers with corresponding authorization are ignored, REALTECH SmartChange even detects impending overwriters in retrospect (downgrade protection).

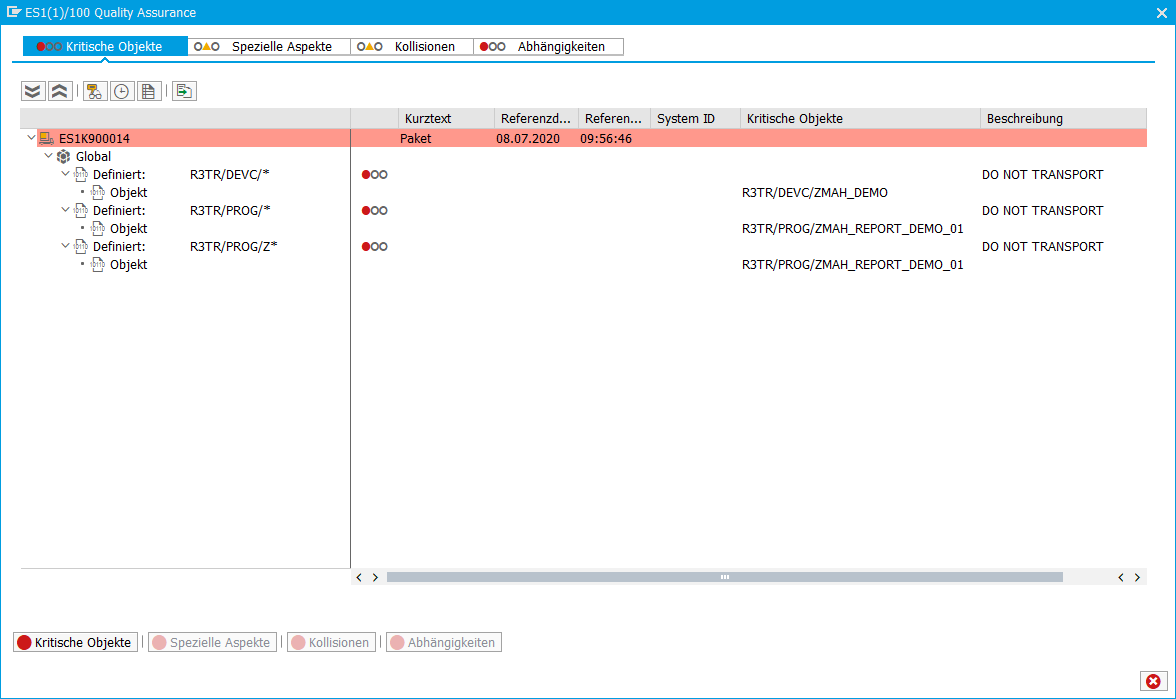

Critical objects

SmartChange checks transports for predefined critical objects (e. g.: Application data, number ranges, structural changes to large tables, etc.).

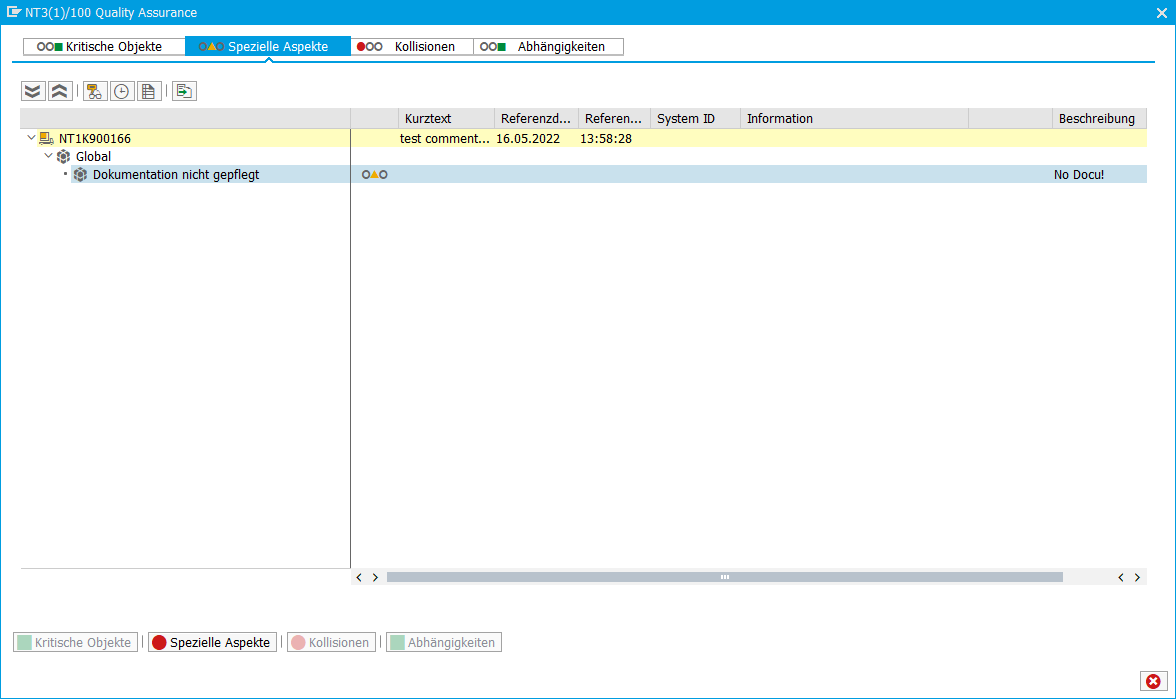

Special aspects

In addition, transports can be checked for certain criteria (special aspects) in order to highlight them in the workflow and thus increase SAP system security. An easy-to-use template helps with quick and flexible customization.

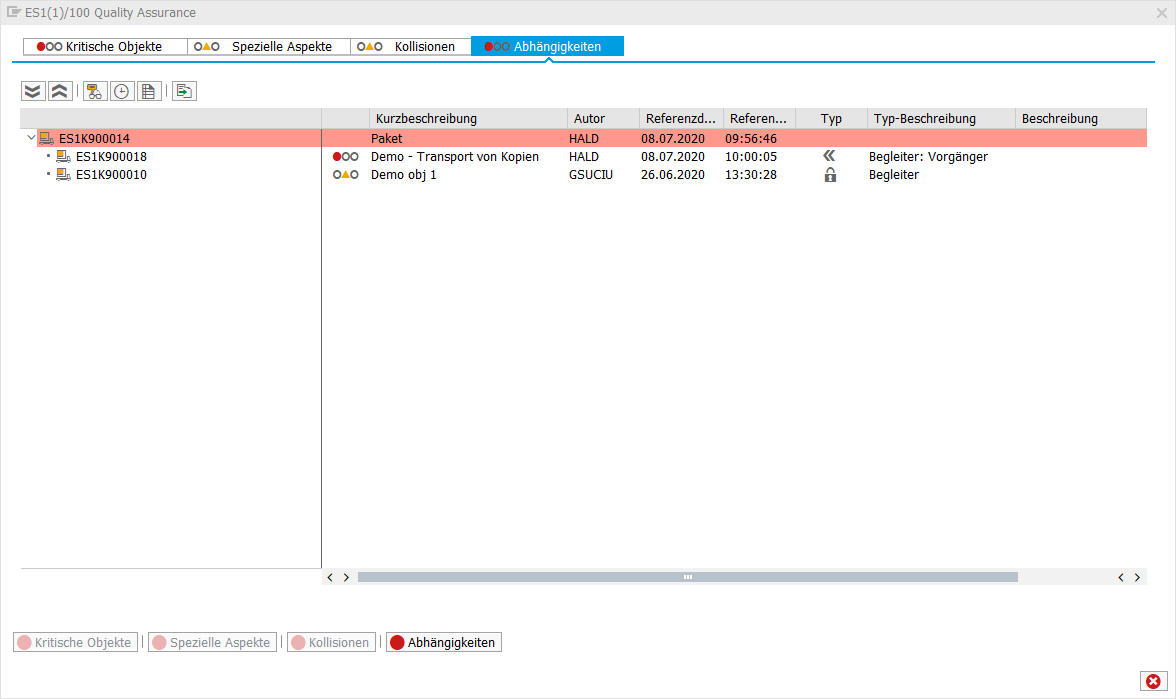

Object dependencies

Logical object dependencies within the SAP landscape can be defined quickly and easily using dependency notes. When incorporating several SAP lines, cross-SAP line dependencies between transports can be taken into account. You can influence both the sequence of transports and the way they are grouped together.

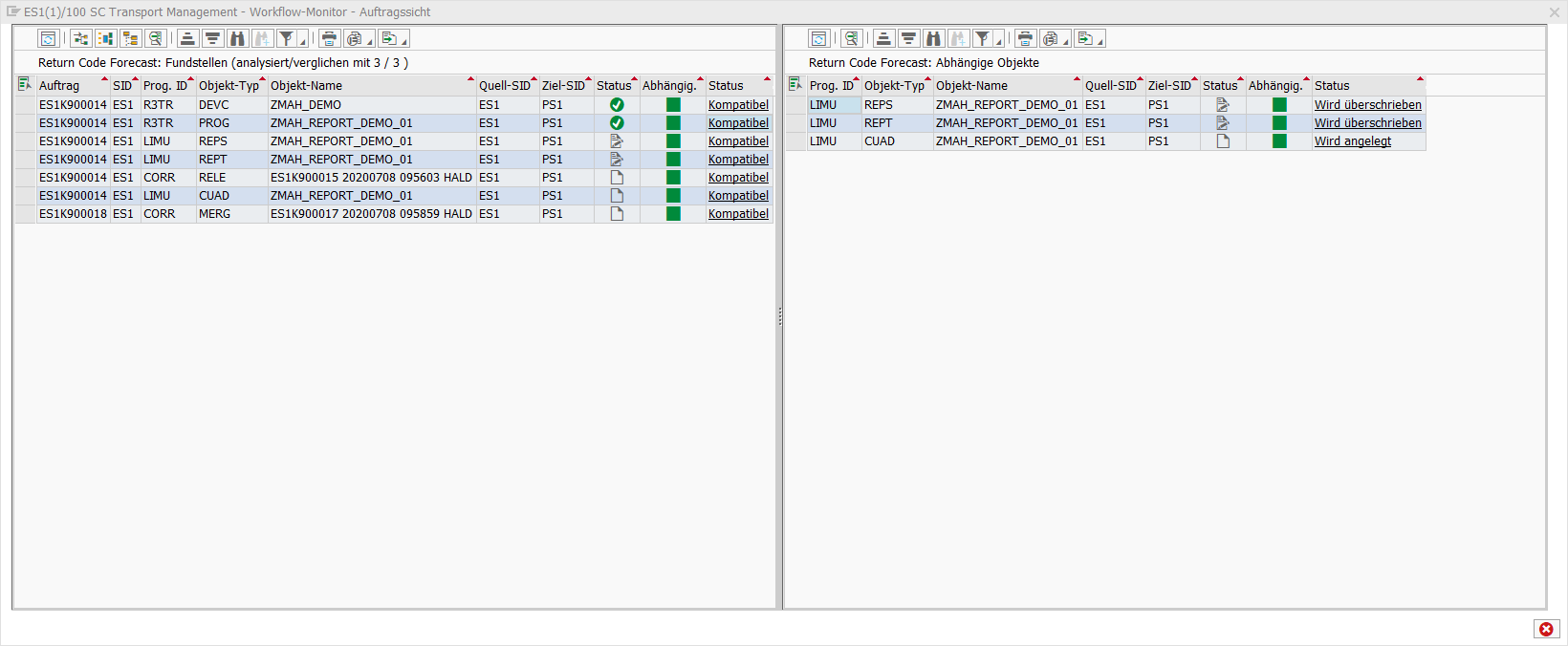

Check for completeness

When checking transports for completeness (return code forecast), a check is performed before importing into a target system to determine whether the objects required for a change are present in the transport request or in the target system.

The completeness check can be performed at all levels (transport, change, release), is fully integrated into the workflow, and functions holistically in transports and target systems.